A comprehensive test strategy is fundamental to achieve the required functionality and reliability and allows minimizing the total cost of ownership of every product. Coordinated process control measures in combination with smart test procedures ensure a fast and efficient achievement of the defined quality levels.

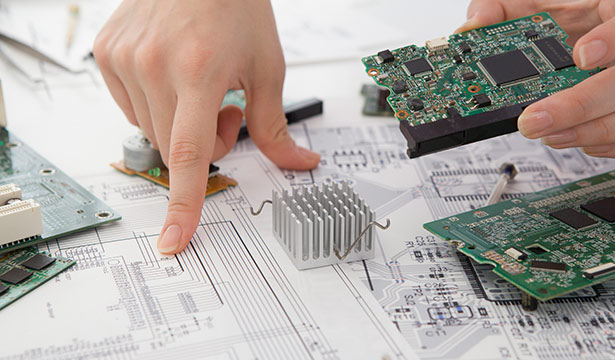

- Elaborated test concepts based on product and process FMEA's considering annual quantities, batch sizes as well as standard and legal requirements

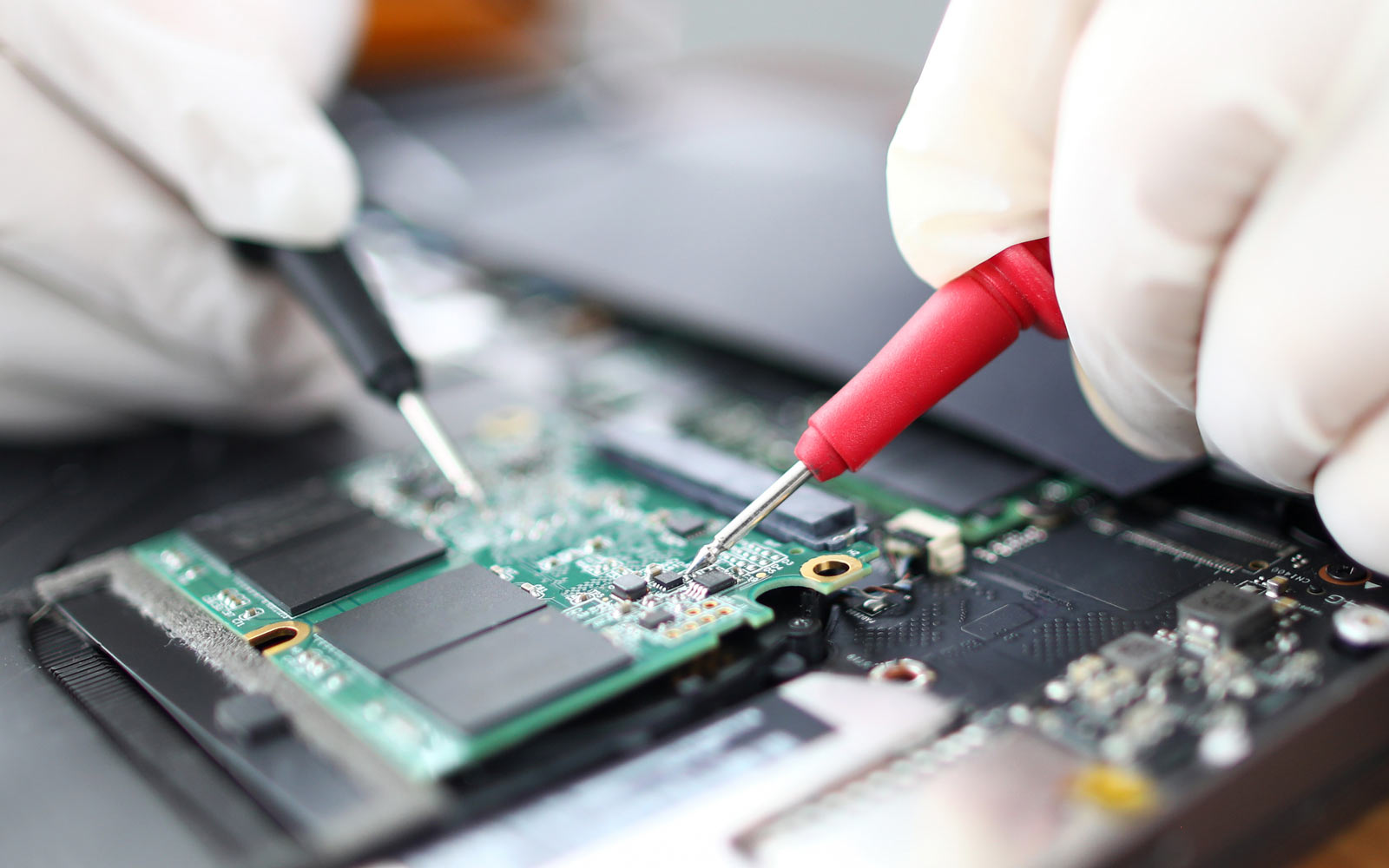

- Development and manufacturing of product specific test fixtures

- Programming of test software

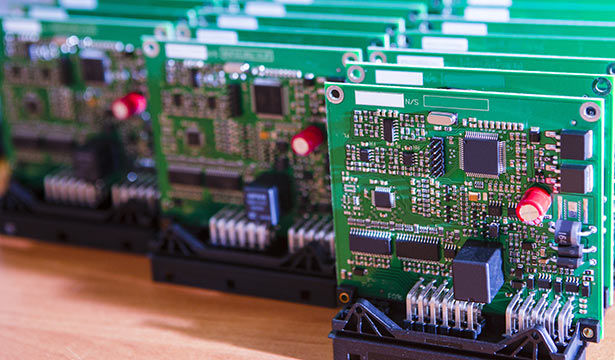

- In-house test equipment for electronics: In-Line Solder Paste Inspection (SPI), In-Line 3D Automated Optical Inspection (AOI), In-Circuit Tester (ICT), Burn in Tester.

- Tailor-made functional testers for all stages of production from the assembled PCB to the final test of the finished product

- High performance test equipment for leak tests using water or air pressure

- Execution of measurement system analyses for validation purposes

- Test database with remote access for customers for traceability of test results